When Is a Warning Line Sufficient Fall Protection for Roofing Work?

This year’s National Safety Stand-Down to Prevent Falls in Construction event took a deep dive into the criteria and uses for warning-line systems. Here are recommendations and tips.

In 2021, according to data from the U.S. Bureau of Labor Statistics, there were 951 fatal work injuries in construction and extraction occupations—370 of those were from falls, slips or trips. In the same year, there were 123 roofing industry fatalities, with 99 of those resulting from falls, slips or trips.

The National Roofing Contractors Association has partnered with OSHA since 2014 to host the annual National Safety Stand-Down to Prevent Falls in Construction weeklong event to raise safety awareness to prevent fall injuries and fatalities.

As part of this year’s free webinar series in May, speakers addressed a variety of safety topics for roofers, including the value of and standards for using warning-line systems.

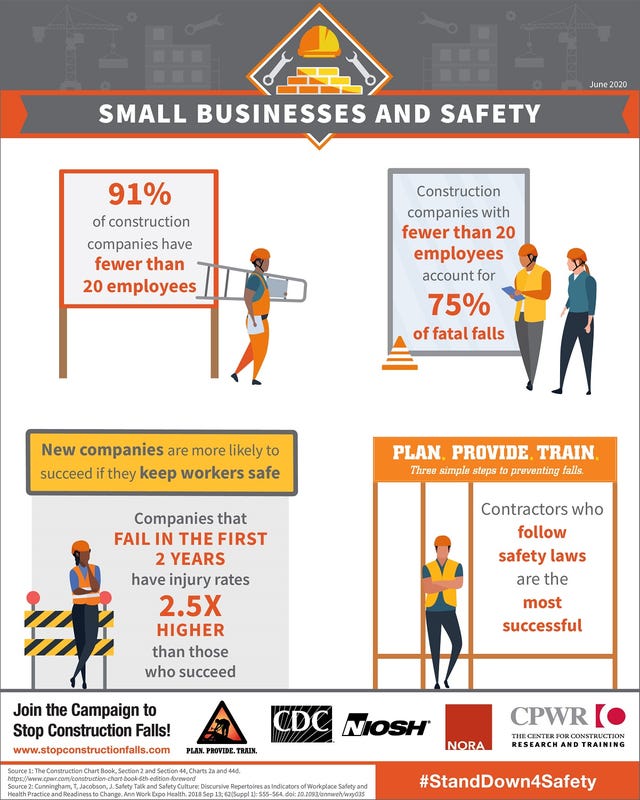

“Small contractors make up a huge section of the roofing industry,” said Rich Trewyn, NRCA’s director of enterprise risk management and the main speaker of the warning-line webinar. Trewyn also included an infographic from the Center for Protection of Workers’ Rights and the National Institute for Occupational Safety and Health that showed 91% of construction companies have fewer than 20 employees. But those companies account for a whopping 75% of fatal falls.

"The impact of falls for small contractors is huge,” Trewyn said. “Before we even get out there, we need to make sure the surface has been prepped and reviewed to ensure nothing will catch our workers by surprise when they are on the job."

Trewyn said there is an express mandate from OSHA to have fall protection for construction employees working on the roof. Between October 2021 and September 2022, the most frequent citation by OSHA was related to fall protection.

Trewyn illustrated that this protection should include (among other things):

Keeping employees safe whenever they are 6 feet or more above a lower level.

Protecting them from falls and from having objects fall on them.

Inspecting the roof surface and having it deemed structurally safe.

Having a protection system in place when sides or edges of a roof or other surface lack a parapet or railing of at least 39 inches.

Fall protection: devices and myths

There are a variety of conventional fall protection devices, according to Trewyn, including guardrails, safety nets and personal fall arrest (PFA) systems. However, he wanted to stress the importance and value of warning-line systems to low-slope roofing work (4:12 or less). On such projects, conventional fall protection devices can be combined with a warning-line system to keep workers safe.

In this context, said Trewyn (quoting OSHA guidelines), “roofing work means the hoisting, storage, application and removal of roofing materials and equipment, including related insulation, sheet metal and vapor barrier work, but not including the construction of the roof deck.”

He went on to explain OSHA’s definition of a warning line: “A barrier erected on a roof to warn workers they are approaching an unprotected roof side or edge.” They contain an area in which roofing work may take place without fall protection systems.

"There are a wide variety of myths and misconceptions out there about when you can and can't use warning-line systems,” Trewyn said. Some of those mentioned include that roofers cannot use them anymore, any trade can use warning lines or a safety monitor, flags are not necessary, cones can be used as stanchions and more.

To help dispel these myths, here are eight criteria from OSHA that Trewyn outlined to keep in mind when utilizing warning-line systems on low-slope roofing work.

All points of access must be demarcated.

Warning lines must be located 6 feet away from the roof edge.

All sides of roofing work areas must be surrounded by the warning line.

When mechanical equipment is involved, lines should be not less than 6 feet from the roof edge parallel to the equipment use and not less than 10 feet from the roof edge perpendicular to equipment use.

The warning lines must be flagged at no more than 6-foot intervals.

The warning line must be between 34 inches and 39 inches in height.

For any stanchions used to secure the warning line, the tip-over force must be at least 16 pounds at 30 inches from the walking or working surface. Stanchions should also be spaced so the lines do not sag below 34 inches.

The minimum tensile strength of the rope, wire or chain must be 500 pounds.

About the Author(s)

You May Also Like