thumbnail

Concrete & Masonry Commercial Products

Modernizing Artificial RocksModernizing Artificial Rocks

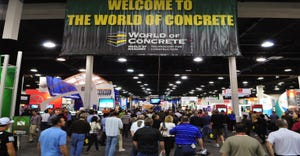

Artificial Rock Sculpting Live! at World of Concrete 2024 demonstrated how combining artistic talent and modern materials can yield structural artwork.

Subscribe to get the latest information on products, technologies and management.

Join our growing community and stay informed with our free newsletters.

.png?width=100&auto=webp&quality=80&disable=upscale)