Storms and fires have devastated parts of the U.S., but 3D-printing construction technology could give hope to areas needing to rebuild quickly.

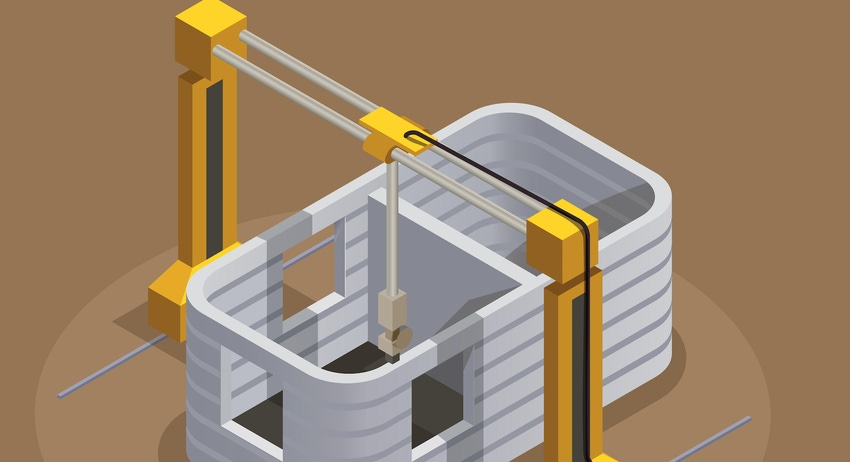

The meteoric rise of 3D-printed concrete is part of an emerging robotics technology trend in the construction industry, and experts like Julien Couverchel, the global business manager of 3D technology for Sika, hope it will revolutionize the way we build and manufacture.

According to Couverchel, industries like car manufacturing and agriculture have been able to increase productivity with the implementation of robotics technology. He envisions a future where precast-concrete plants operate like automotive assembly lines.

Couverchel said 3D-printing technology will increase efficiency on jobsites and can compensate for the skilled labor shortages around the world.

“3D computer printing should be used, not only because it’s cool or trendy, but really because it adds value to the building process to gain efficiency,” he said.

Couverchel joined other representatives from Sika at a forum, held recently at the World of Concrete in Las Vegas, that addressed innovations in 3D-printed construction technology.

Lyndsay Castle, marketing coordinator for Sika, talked about some of the complaints she hears about the technology.

She said customers often ask how they can get rid of the layered lines that are commonly associated with 3D builds.

“You can get rid of the lines with after products once it’s printed,” she said. “Or you can add a tool to the nozzle head (of the machine) that will eliminate the lines and just smooth it out as it prints.”

Another drawback she mentioned with the technology involves color.

She said one disadvantage to using color is that the inside walls of a home will be the same color as the home’s exterior.

Regardless, Castle said she believes 3D printing is going to “take off” because of the labor shortage.

Noah Callantine, a process engineer with Sika, said time is everything when builders are out in the field.

“We should be able to consistently print until it is finished,” he said. “We should be able to do it all in one shot.”

Callantine said consistency with 3D printing depends on the material being mixed, and that batch-mixed material is less likely to perform consistently in the printer.

“But if you use a continuous mixer, you get a steady, continuous flow of material that’s evenly dispersed all the way through,” he said.

3D printer companies expanding

Sika, as a company, claims it developed a “perfectly precise print head” and boasts of being the only organization that can supply all technologies needed for 3D printing from a single source.

Other companies operating in the same space include firms like COBOD International, which says it leads the world in volume with the most printers sold globally to date, according to its website.

Recently, PERI Group, a Germany-based company that holds a minority stake in COBOD, teamed up with CIVE, a Houston-based construction company, to begin work on what it says is the first two-story 3D-printed home in the U.S.

Construction of the home, which is slated to be 4,000 square feet, began in July 2022. The printing process is ongoing.

Hachem Domloi, CIVE’s president, said that the Houston home’s printing process is taking several months because it is a research project. He also confirmed that the project is printing on reduced hours, due to its location in a residential neighborhood.

The home, which is slated to be 4,000 square feet, began to be printed in July 2022. Printing of the home is ongoing.

In a post on its Facebook page, CIVE said 3D printing could have immensely positive impacts for parts of the U.S. that have recently been devastated by natural disasters.

“Hurricane Ian has leveled parts of the Florida peninsula,” CIVE wrote. “3D printing could, in the near future, be a viable option for rebuilding those homes in a matter of days versus months and/or even years in some cases.”

About the Author(s)

You May Also Like