Getting reliable results from testing of concrete cylinders requires that they be cured properly.

January 11, 2021

Every winter in the concrete industry when everyone is trying to place concrete even though it is cool outside, concrete compression test cylinders are not being cured properly. ASTM C-31 recommends that for the initial curing, test specimens should be submerged in water and the water temperature should be maintained between 60° and 80° F. But when the ambient temperature is 50° during the day and 5° to 10° F in the early mornings that is not possible without some extra protection.

Five test cylinders fit nicely in the Tractor Supply bucket.

The Command Center sensor in the bucket measuring the water temperature.

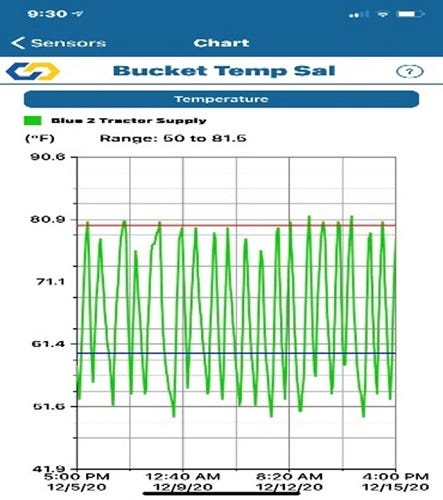

The Command Center sensor recorded and plotted the temperature over a 10-day period. The ambient air temperature ranged from 5° to 45°.

To solve this problem, we started with a heated blue bucket from Tractor Supply, cost about $50.00. This bucket holds five 4x8-inch test cylinders. The bucket is designed to keep livestock drinking water from freezing during the winter. The water temperatures measured with a Command Center sensor with no test cylinders indicated the water temperature stayed between 50° and 80° overnight. This was in early December when the ambient air temperature was a low of 6° and a high of 45°. The bucket needs 110-volt power and a lid made from a 2-inch thick piece of Styrofoam to keep the heat in the container with water and the test cylinders. This appears to be a usable and economical method of initial curing.

A five-gallon bucket can hold four test cylinders. This is the setup with a fish-tank heater, the Command Center sensor. and a high-low thermometer.

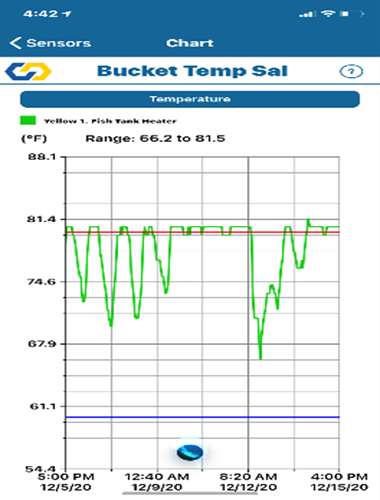

A Command Center printout of the water temperature using the fish-tank heater ranged from 63° to 80°.

The next method we tried for keeping the water warm was a fish-tank heater manufactured by Free Sea, Model FS-28, cost $25.00. The fish tank heater has a thermostat which was set at 60° and placed inside a 5-gallon bucket with water. The lid was a 2-inch piece of Styrofoam. The measured temperature of the water overnight was between 65° and 81°, measured with the Command Center temperature sensor. The fish tank heater can also be used with a 10 x 20-inch cooler filled with water that holds up to eight 4x8 test cylinders. Measuring the temperature with a high-low temperature recorder would be smart.

The setup with the Powerblanket wrapped around a five-gallon bucket with a Styrofoam lid and a Command Center sensor to continuously measure the water temperature.

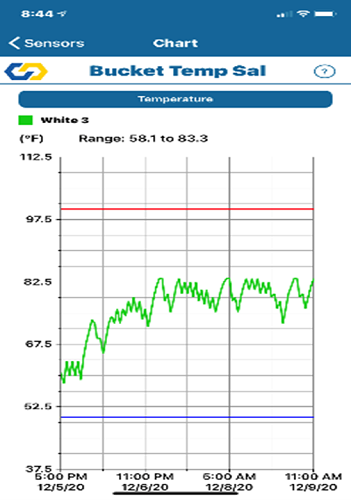

A Command Center plot using the Powerblanket shows that the temperature ranged from 58° to 83°.

The last method we tried used a Powerblanket concrete curing blanket to heat a 5-gallon pail. This can be purchased from Powerblanket for about $100.00. Because the blanket heater was on all the time, this method heated the water to over 90° when measured with a high-low sensor. We installed a timer that allowed the blanket to be on for one hour and off for one hour. This appeared to be another acceptable method of keeping four 4x8 test cylinders at the proper curing temperature with the caveat that only four cylinders fit in a 5-gallon bucket.°of 60° to 80°F. These methods performed well at overnight temperatures as low as 0°F but only works where there is access to 110-volt power at the job site overnight. A solar-powered battery to run this equipment overnight in the field would be advantageous since 110-volt power is not always available and if the battery is stolen you will not lose a big investment. Any advice on this by the concrete industry would be appreciated.

This is the experimental set up in real conditions showing (from left to right) the fish tank heater in the yellow bucket, the Tractor Supply heater in the blue bucket, and the Powerblanket heater over a white bucket. With the warm water in the buckets the snow on the Styrofoam did not melt after 3 days.

The experiment was done in conjunction with Michele’s Ready Mix, Rock & Recycle, Inc. in Gallup, New Mexico in December of 2020. The mean temperature over the month was 30° with a high of 65° and a low of 2°.

About the Author(s)

You May Also Like