Creating a “Zero-Waste” Roofing Industry

In this Q&A with Mycocyle CEO Joanne Rodriguez, she discusses the future of reusable resources in roofing.

According to the EPA, each year about 14 million tons of asphalt shingles end up in U.S. landfalls.

According to the EPA, each year about 14 million tons of asphalt shingles end up in U.S. landfalls.

“When you remove a roof, you have a lot of trash, not just any trash, but construction and demolition debris.

Until now, the roofing industry and other asphalt and chemical manufacturers have not been able to achieve zero-waste because the products manufactured were ultimately contaminated with toxic constituents,” explains Mycocycle Inc. Founder & CEO Joanne Rodriguez.

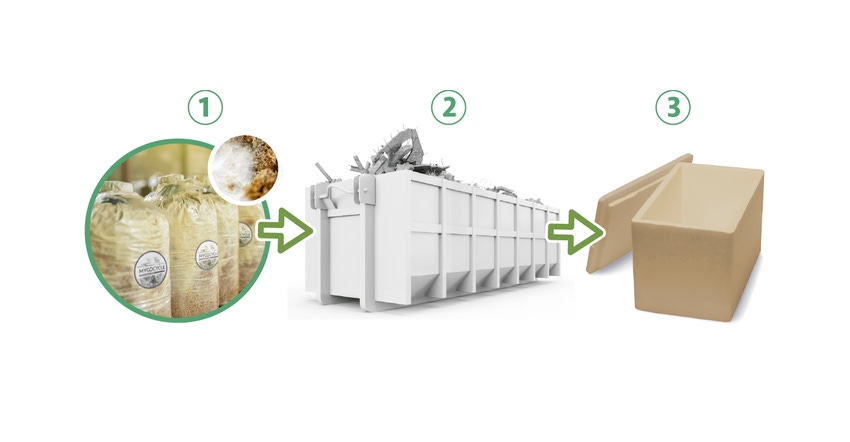

Rodriguez envisions a future where roofing could be a “zero waste” industry and is doing her part to help achieve this. Mycocycle uses mushrooms to remove toxins from waste. Once the toxins are removed, the biomaterial can be re-rendered for commercial or industrial use into new products.

Rodriguez has been recognized for her innovation by Forbes Magazine, FastCompany, and the EPA. Prior to founding Mycocycle, she headed the environmental consulting firm GreenStructure and continues to be recognized as a sustainability leader in the construction products manufacturing industry.

We sat down with Rodriguez to discuss how she is shifting the paradigm on how we view waste from a burden to a reusable resource.

R&E: Can you tell us a bit more about how Mycocycle is “disrupting” the roofing and construction industries?

RODRIGUEZ: Having come from the industry, I knew that there were two growing concerns around roofing and building materials: 1) How to dispose of them and 2) How to stay chemically compliant.

It had been my experience that both of these were held as separate concerns when realistically, looking at how they are tied together makes driving solutions in this space a bit easier. Building materials are the fourth largest waste stream being landfilled in the U.S. and No. 1 in Europe. Developing a path forward that could allow for greater reuse of materials seemed to make perfect sense to me. This required examining why they weren’t being reused and the long-term issues associated with landfilling or burning them. Discovering that mushrooms could not only mitigate the risks around long-term chemical release of materials in landfills but could also create a new biobased material for reuse into new applications should be a game-changer for the industry.

Through Mycocycle’s process we can now check both of the industry boxes noted above by removing volumes of waste from overburdened landfills and creating mushroom-based material inputs for new products. And the third significant aspect of what we offer, which should likely be the first: we help lower greenhouse gasses related to waste management activities by almost 3 metric tons of CO2 emissions for every 1 ton of waste diverted. This is how we are disrupting the roofing and construction industries.

R&E: In addition to addressing roofing waste once it’s already created, how are you helping manufacturers create sustainable roofing products?

RODRIGUEZ: Currently this is a blank canvas. As we don’t manufacture materials, but deliver the treatment process, we are working side-by-side with global manufacturers to determine the best use of their post-treated roof products. Some are reticent to reuse the byproduct of our process in new roofing products, particularly those that are involved in exterior waterproofing, because it is biobased. Without treatment the mycelium (the mushroom material) will degrade quicker when exposed to weathering. These manufacturers, however, are considering usage into insulation products, composite boards, fillers for reinforcement, additives for spray foams and coatings, or even to create new packaging for their products to be shipped in and on.

The savvy building manufacturers are working across divisions to take the waste from their roof manufacturing and place it into other divisions' products where long-term weatherability isn’t as great a concern (i.e., flooring, acoustic tiles, foam board, MDF/HDF alternatives). This is the essence of circularity, and we love the opportunity to innovate with them!

R&E: Can you tell us how you got into the business of driving sustainability and why it’s a passion for you?

RODRIGUEZ: It goes back to being a kid and just being outside all the time. Nature is inspiring to me. Fast forward to college where I took a sustainability course, taught by a professor from Rubbermaid. Even back then we were talking about the importance of removing materials from the waste stream—it was all about recycling. While in the industry, you could see the growing need to “green” our processes and drive circular reuse of materials. As data points emerged around the amount of energy, greenhouse gasses, water, etc. buildings used—from start to finish—it really became a primary focus for me to develop a more sustainable path forward.

R&E: Make the business case for our roofing audience and using sustainable and reusable products—why should they make the switch?

RODRIGUEZ: Aside from being good business, the circular economy accounts for roughly $2 trillion in economic impact, their clients are already telling them they want this. In 2019, BASF conducted a study across roofing contractors, distributors and architects involved with asphalt shingles. The study showed that roofers in particular are becoming more interested in recyclable asphalt shingle products. It also showed that roofers held a huge interest in reducing the environmental impact of asphalt products.

The contractor sector is faced with the brunt of rising costs associated with disposal of construction and demolition waste too. It seems there is frequently a disconnect from the manufacturing sector through to the contractor/building owner sectors. Manufacturers will claim that their clients aren’t asking for sustainable materials, but that just isn’t true. Owners are demanding cleaner products too, with less impact on the environment. They want to go zero waste since waste is something they generally can control, but the building material waste is either buried or burned.

Big picture? I won’t have to make the case because the economics and increasing regulatory demands will make using sustainable products mainstream. It will become a situation where if you aren’t making your processes and your products more sustainable you will be on the outside looking in and putting your entire operation at risk. I say jump on the bandwagon now, so you control your narrative! Being proactive is always more lucrative than being reactive.

R&E: Congrats on Mycocycle being named a Momentum award nominee as an “industry disrupter.” What does this recognition mean to you?

RODRIGUEZ: Thank you! Gaining this recognition is huge for us. It sets the table for the startup ecosystem in Chicago and beyond to recognize us as a real player in this field. The fact that we were nominated, and we have no clue who the nominator was, makes it even that much sweeter. It can be a “lonely” task building a business, especially during the pandemic, so knowing that we are on someone’s radar is really special.

About the Author(s)

You May Also Like