In Part 4 of this series, concrete historian Luke Snell describes how the farmer and his helpers mixed the concrete without a mixer.

The farmer now has quality materials and a mixture design tailored to what he needs. Now it’s time to make the concrete. The self-help books of the time tried to simplify the process by providing pictures of each step, which may appear simple in a book, but making concrete is hard work.

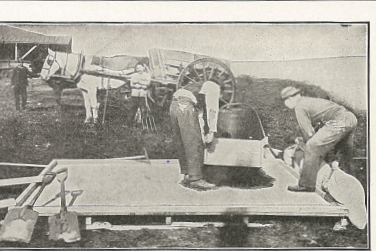

The first step (Picture 1) is to gather all the necessary materials and to have a work platform to make the concrete. The work platform can be any level spot. In this picture, the farmer built a working platform out of wood.

1. Gathering all the materials onto the work platform.

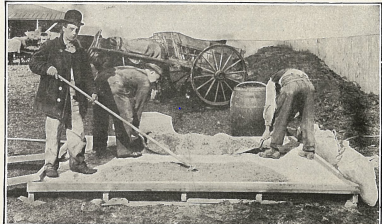

The next step (Picture 2) is to accurately measure the amount of sand needed for the mixture. The farmer used a bottomless box (see Part 3, Getting the Right Mixture) to get the volume of sand correct according to the mixture design. In this picture the bottomless box looks to be 3 cubic feet.

2.. Making sure the volume of sand is correct.

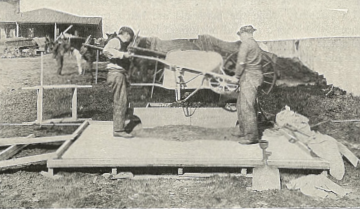

The farmer added the cement directly onto the sand (Picture 3). Note that the farmer did not need to measure the amount of cement in the bottomless box since it came in a 1 cubic foot bag. The cement bags appear to be made of cloth. These bags could be recycled if returned to the cement company undamaged.

3. Adding the cement on top of the sand.

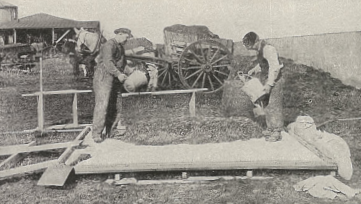

They would then mix the sand and cement together (Picture 4). They know they are done when the sand and cement appear to be uniformly mixed.

4. Mixing together the sand and cement.

Now they are ready to add the rock or coarse aggregate (Picture 5). They placed the bottomless box directly on the cement and sand pile. The wheelbarrow and the ramp made this process a little easier.

5. Adding the rock to the sand and cement.

After mixing the rock into sand and cement, water would be added. A predetermined amount would be measured and added so that they would not get too much water into the mixture (Picture 6).

6. Adding water to the sand, cement and rock.

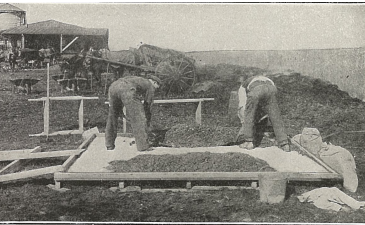

The final step is mixing all the ingredient together. They knew they were done when the entire mixture was of uniform appearance (Picture 7). In the picture, they divided the pile into two parts for ease of mixing. They would put the piles back together as a final step.

7. Final mixing of the concrete.

If you have ever mixed concrete by hand, you know how tiring this work can be. Unfortunately for the farmers, their work is not done. They now must place the concrete--without pumps, conveyor belts, power buggies, or vibrators, so they still have a lot of work to do. The next (and last) article in this series will discuss how the farmer placed the concrete.

About the Author(s)

You May Also Like